Varnish is resin. What we want to talk about in this article is the vanish which is applied in insulating processes. Varnish is widely used in electrical equipment, such as motors, transformers, coil immersion, etc., to provide insulation, moisture, corrosion protection, fixation, and even heat dissipation. According to the scope and methods of operation, it can be classified by impregnating, covering, silicon steel sheet, anti-corona.

We can choose suitable varnish the characteristics of usage, process mode, environment friendly, regulations requirement, safety certification and etc.

The most used of the above classifications is by solvent form. Here's a look at the characteristics of different solvent categories:

Water soluble:Water-based insulating varnish having excellent bonding characteristics and chemical resistances. It is environment friendly, low organic volatile matter (VOC), no air pollution, meet the requirement of the United States clean air standard. Water soluble insulation vanish need to be diluted with RO water/ water according to the appropriate proportion after stirring, in 20 to 30% resin solid composition. Dip tank pH should be maintained around 8, and must often check the viscosity and pH value of vanishes.

Solventless varnish:Compared with solvent-based varnish, non-solvent varnish has the advantages of Flexible for excellent noise suppression, rapid drying, low volatilization, environmental protection, low baking temperature, convenient storage and so on. However, non-solvent varnish should be used with curing agent (initiator). How to choose the appropriate proportion of curing agent is the key point to improve the production efficiency. Under normal situation, the amount of curing agent added is about 1%~3% of varnish. The more curing agent added, the faster the reaction is, the better efficiency I’s. But at the same time the stress becomes higher, and the cost is slightly higher. But the smell of non-solvent varnish is stronger than that of solvent varnish. However, because of the low volatilization of the non-solvent varnish, the odor will not harmful to the human body.

Solvent varnish:The solvent - based varnish contains lower solid content and higher organic solvent content. Although the solvent type used is less odorant than the non-solvent type, but most of the volatile gas has a certain toxicity. But because of the simple use, and some other unique characteristic and related low cost. Solvent varnish still has some market share.

The range of water-based varnishes was developed to meet the ever-more urgent requirements to reduce emissions into the atmosphere and safety in the workplace; without forgetting the growing need to improve mechanical bonding and insulation of the latest generation motors and transformers.

At present, almost water based insulating varnish used in motors and transformers may control the pH value of the dip tank. Take ElantAS 1000-70 as an example, usually after opening tank: the pH value of water based varnish should be controlled between 8.0-9.0. It is easy to preserve water-based varnish when the viscosity and pH of the water are checked frequently at all times. If the water-based varnish becomes thick or opaque, it needs to be adjusted immediately. By adding water, the viscosity usually returns to normal. Or add small amount of DMEA, pH agent can improve the pH value of varnish.

Water soluble varnish water pH value detection method:Generally, there are two methods to detect the pH value of water soluble varnish, colorimetric method and potentiometric method which based on Nernst equation.

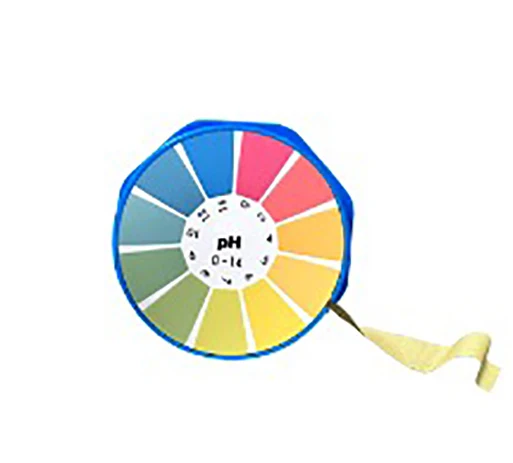

The advantages and disadvantages of colorimetric method to measure the pH value of water based varnish:Firstly, make sure test range of your pH test paper meet you requirement. Take a test paper from the case and put in on the surface of glass piece, and use a clean glass rod dipped in the vanish can and drop in the middle of the pH test paper. Observe the change of color after stability as user guide. Match the colour reading against the indicator chart in the pH test strips’ packaging. Water-based Vanli water state is similar to glue, high viscosity (gel), not easy to be absorbed by dry pH test paper, and some models of water-based Varnish will have a light-yellow color. It will affect the final color of the pH paper display. According to the instructions of water-based varnish , pH should be controlled in the range of 8.0-9.0 pH. So it is not easy to get the correct result by using of pH test paper.

Potentiometric measurement of pH value can achieve accurate result. The most commonly used pH electrode in laboratory is pH glass electrodes. Following is the user guide for pH glass electrode:

The following points need to be pay attention, when the glass pH electrode is used to test the pH value of water based Varnish:

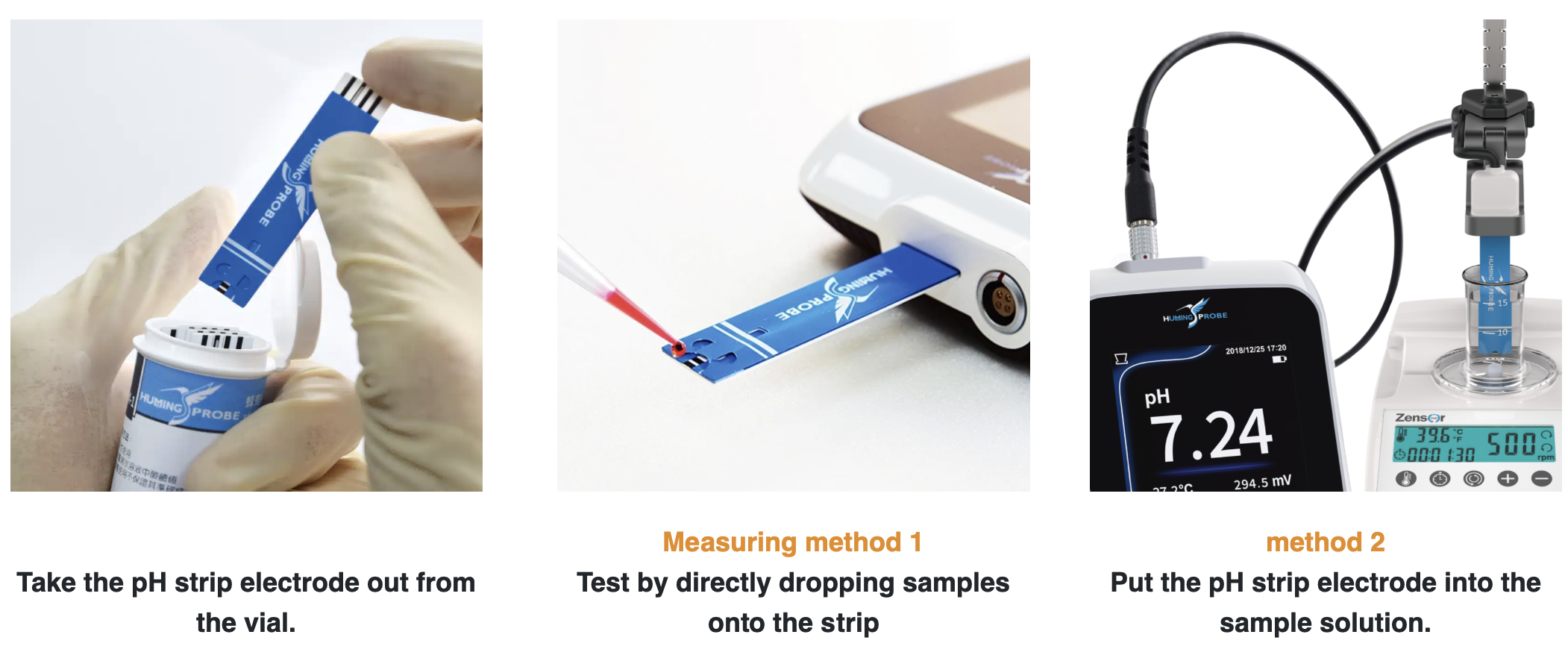

Test pH value with Humming probe pH strip:

Test pH value with Humming probe pH strip:Each test strip of humming probe has been calibrated and verified using NIST traceability standards before leaving the factory, so you can simply take the test strip out of the vial and test pH directly. Each batch of calibration information is printed as QR code on the cap of the vial. Scan the QR Code when using the strip for the first time to load the technical parameter of the pH strip into the meter, and then the pH measurement can be performed directly. Unlike traditional glass electric appliances, the Humming Probe is extremely convenient, not requiring traditional and complicated calibration steps. Additionally,Additionally, disposable design and single use pH sensor is very suitable for test water based varnish. A brand-new test strip can used for each use and requires no time-consuming cleaning or maintenance after testing. For viscous or easily adsorbed samples or in combination with various special treatments, it breaks through the limitations of traditional glass electrodes and provides you with more applications.

Comparison of differnt pH detection methods for water based Varnish:

Comparison of differnt pH detection methods for water based Varnish:In the table below, we compare the performance of each of the above three pH measurement methods in terms of ease of operation, accuracy, calibration, sample requirement, storage and maintenance, price, and sample cross-contamination

| Glass electrode | HUMMING PROBE | Test Paper | ||

|---|---|---|---|---|

Product / item |  |  |  | |

| Operability | ||||

| Operability | Difficult | Easy | Easy | |

| Accuracy | ||||

| Accuracy | High | High | Low | |

| calibration | ||||

| calibration | Needed | No Needed | No Needed | |

| Sample volume | ||||

| Sample volume | More(5~10 mL ) | Less(1~20 μL) | Less(50~100 ML) | |

| Maintenance | ||||

| Maintenance | Difficult | Easy | Easy | |

| Price | ||||

| Price | High | Low | Low | |

| Cross-contamination | ||||

| Cross-contamination | Possible | Disposable | Disposable | |